Common Problems in Vibration Test Fixture Design: Solutions & Top Tips

Vibration testing is a crucial step in product development. The success of these tests depends not only on the quality of the product but also on the design and execution of the fixtures or jigs used to secure the items being tested.

In this blog, we explore common issues engineers face when designing and producing vibration test fixtures, and provide practical solutions to overcome them. Here are our top tips for designing an effective vibration test fixture.

Common Problems in Jig or Vibration Test Fixture Design

1. Fixture Design Mismatch

- Problem: The fixture design doesn’t align with the shape or mounting points of the test item, leading to misalignment or damage during testing.

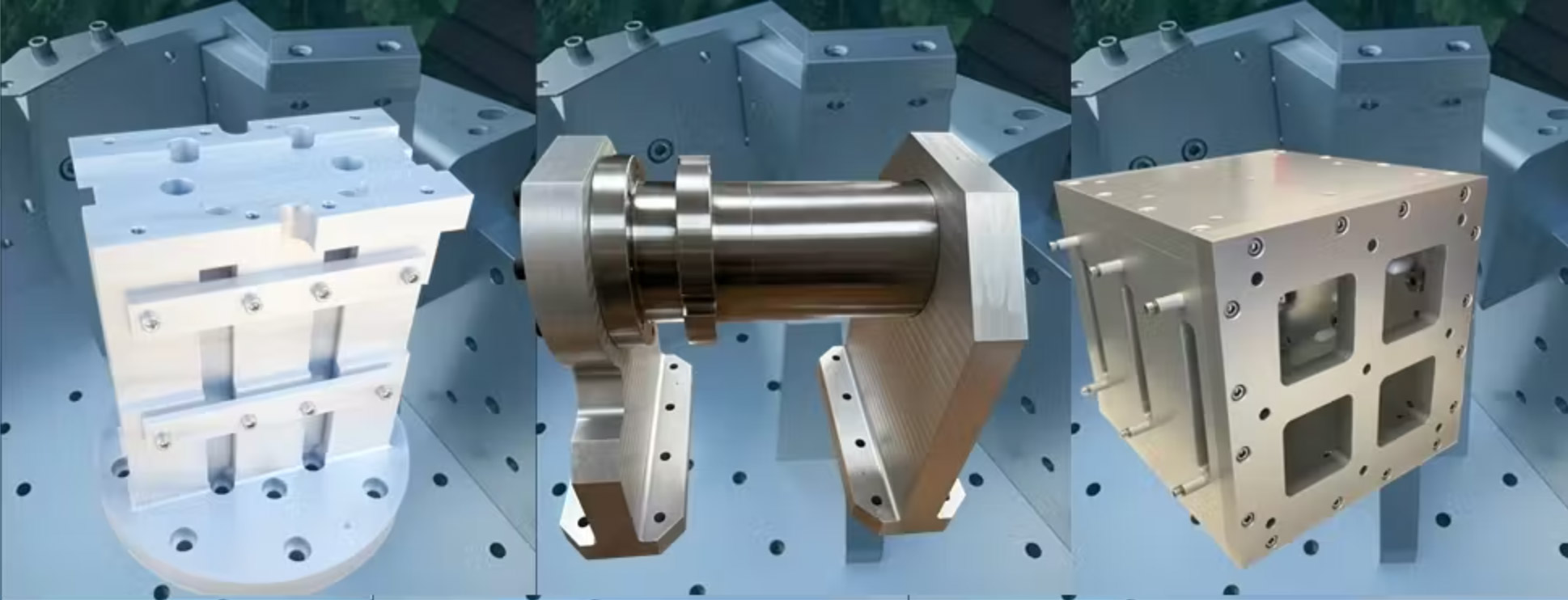

- Solution: Gain a thorough understanding of the product’s geometry and attachment points. Collaborate with the product design team to ensure proper compatibility, and use CAD software to create a custom fixture that fits the item’s contours precisely.

2. Inadequate Attachment and Fastening

- Problem: Weak or improper fastening may cause the test item to detach, undermining the test’s safety and validity.

- Solution: Select robust, suitable materials such as aluminium for the fixture. Use reliable clamps, bolts, and fasteners, and regularly inspect them to ensure secure attachment throughout testing.

3. Resonance and Amplification

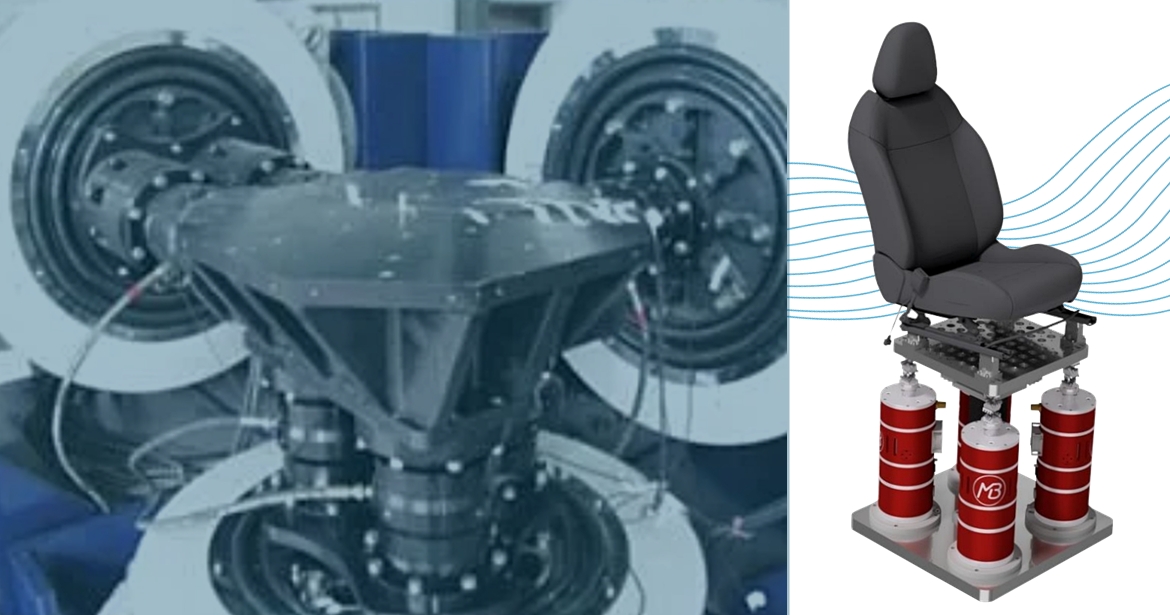

- Problem: Poor fixture design can result in resonance and amplification of vibrations, distorting test results.

- Solution: Calculate the fixture’s natural frequencies to avoid resonance. Use shock absorbers or vibration isolation mounts to dampen vibrations, and modify the fixture design to avoid resonant frequencies.

4. Test Item Overloading

- Problem: Overloading the fixture with a heavy or oversized test item can lead to structural damage or failure.

- Solution: Always perform load testing to verify that the fixture can support the anticipated forces during the test.

5. Inadequate Flexibility

- Problem: Fixtures that are too rigid may not accommodate the necessary movements or vibrations required for the test.

- Solution: Incorporate adjustable mounts or flexible components to suit various testing scenarios, ensuring these adjustments are easy to make and maintain stability.

Top Tips for Designing a Vibration Test Fixture

1. Collaborate with Design Teams

Work closely with the product design team to fully understand the test item’s geometry, attachment points, and any specific requirements. This collaboration ensures the fixture replicates real-world conditions accurately.

2. Prioritise Material Selection

Choose strong and appropriate materials, such as aluminium or steel, that can withstand the forces and vibrations expected during the test.

3. Calculate Natural Frequencies

Utilise simulation tools like finite element analysis (FEA) to determine the natural frequencies of your fixture, and ensure these do not interfere with the accuracy of your testing.

4. Incorporate Damping Techniques

Add shock absorbers or vibration isolation mounts to dampen unwanted vibrations and avoid resonance, protecting both the fixture and the test item.

5. Load Testing

Perform load testing to ensure your fixture can handle the expected forces, preventing structural failure and ensuring safe, accurate testing.

6. Flexibility and Adjustability

Design your fixture with adaptability in mind, allowing adjustments for different testing scenarios. Ensure that these adjustments are simple to perform while maintaining fixture stability.

7. Regular Maintenance

Frequent inspection and maintenance are key to the long-term effectiveness of your fixture. Address any signs of wear and tear promptly to avoid issues during testing.

By following these steps, you can design a vibration test fixture that delivers accurate results, reduces the risk of failure, and ensures the safety and reliability of the products under test.

Visit the CentraTEQ Ltd website for more information on Common Problems in Vibration Test Fixture Design: Solutions & Top Tips