Development, testing and qualification of ruggedised optics

18-07-2023

Resolve Optics has recently expanded its lens testing capabilities by installing and commissioning a state-of-the-art vibration test center. This new addition enhances the company's in-house equipment suite for lens testing.

To achieve this expansion, Resolve Optics partnered with CentraTEQ, a renowned supplier of cutting-edge vibration testing solutions. Through this collaboration, Resolve Optics obtained the ETS MPA101-L215M Vibration Shaker and DTC Venzo 880 controller, both certified and calibrated in accordance with ISO standards. This strategic partnership with CentraTEQ empowers Resolve Optics to perform various forms of vibration testing, as well as specialized vibration and shock qualification tests tailored to meet specific customer requirements.

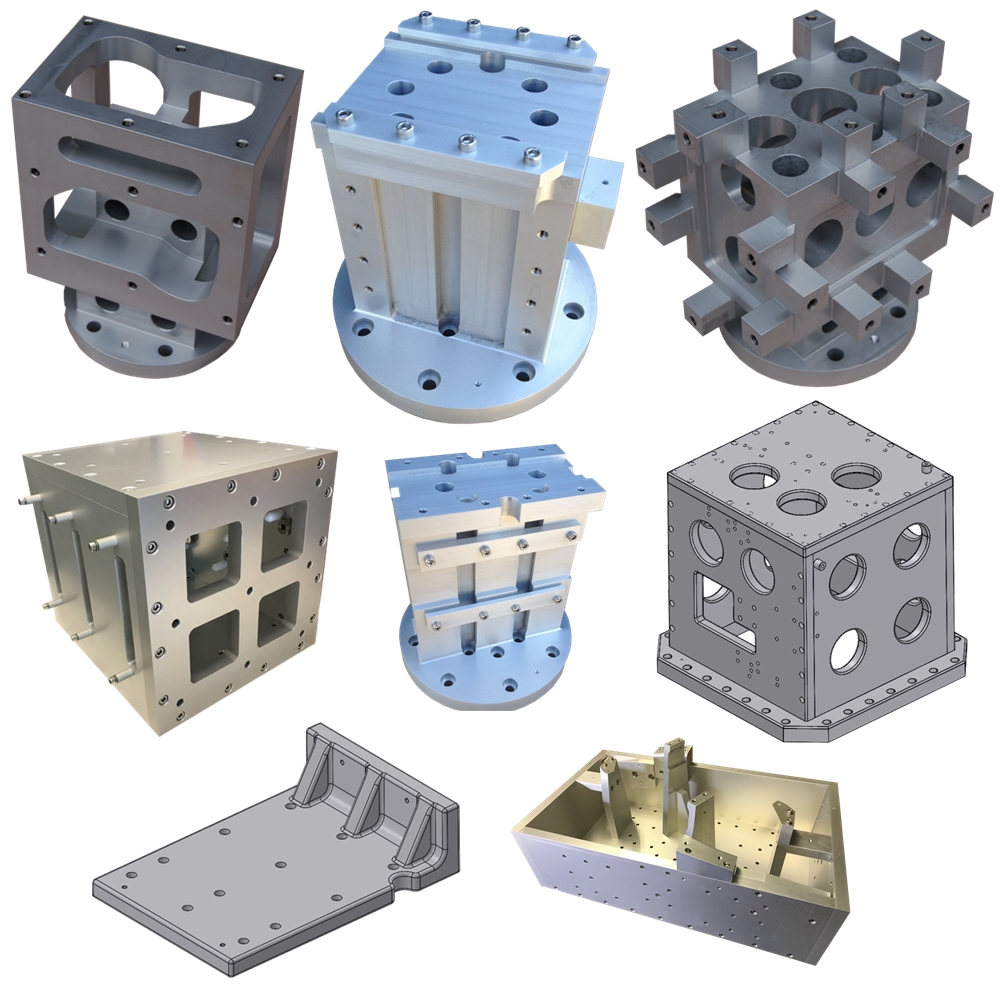

Lenses utilized in demanding applications such as harsh industrial inspection, military operations, and space exploration often face challenging conditions including vibrations, shocks, temperature variations, radiation, and contaminants. Drawing on decades of experience, Resolve Optics specializes in developing custom lenses optimized for such environments, providing OEM quantities that can reliably perform under these harsh conditions. The ruggedization process typically involves simplifying lens designs and reinforcing the mechanical structure of the optical system to ensure focus stability in the presence of shock and vibration.

Mark Pontin, Managing Director of Resolve Optics, emphasized the increasing importance of environmental testing as a selection criterion for clients seeking ruggedized lenses or optical systems. He stated that vibration and shock testing, as a common requirement for "proof of operation," has become a prevalent environmental test conducted by the company.

"Our new vibration test facility allows us to conduct various tests, including Random, Random on Random, Sine Sweeps, and Classic Shock tests. We provide detailed reports on the results obtained from these tests," said Pontin. This enhanced capability enables Resolve Optics not only to qualify the ruggedized lenses it supplies but also to offer vibration testing services for customers' systems.

Pontin further highlighted the capabilities of the new shaker, stating, "Although our new shaker may be considered small in the world of vibration testing, it can handle up to 20 kg at 9 g rms and 12 kg at 14 g rms, making it a highly capable machine."Visit the CentraTEQ Ltd website for more information on Development, testing and qualification of ruggedised optics