Modern Vibration Testing: Key Challenges Facing Engineers Today

Vibration testing is still vital for proving product durability and performance across many industries. But as products become more complex and test requirements evolve, engineers and specifiers face a new set of challenges.

Increasing product complexity demands flexible test solutions

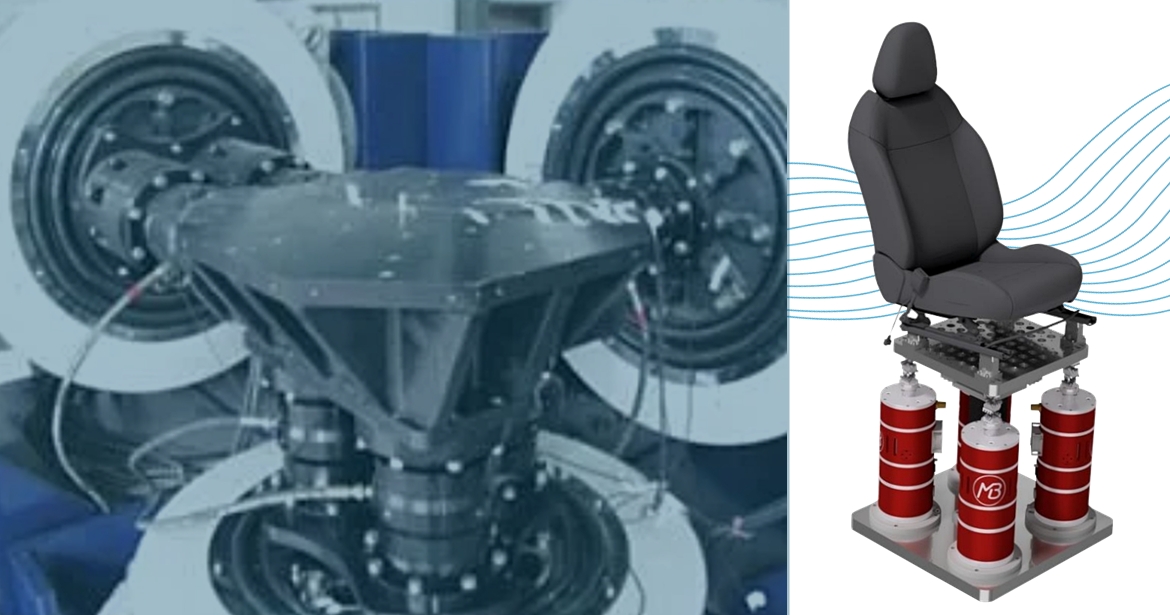

Modern assemblies often combine lightweight structures, embedded electronics and intricate mechanisms. These mixes create vibration behaviours that are hard to predict and harder to replicate with confidence. Effective testing typically requires shakers with very wide frequency coverage (from below 5 Hz to beyond 3,000 Hz), multi-axis capability to reproduce real-world excitation, and adaptable force and stroke to handle everything from handheld devices to large EV battery packs. Teams need systems that cope with this variety without constant reconfiguration or workarounds.

Accuracy and repeatability under endurance conditions

Long-duration reliability matters as much as peak performance. It’s not just hitting a target acceleration, but holding it over extended cycles, often alongside thermal or environmental stress. Common issues include heat build-up during high-force or long-stroke tests, closed-loop control that overshoots, drifts or underperforms against tight automotive and aerospace specs, and unintended system harmonics or fixture effects that distort the intended profile. To meet standards such as MIL-STD-810, IEC 60068 and ISO 16750, labs need shakers and controllers that maintain tight control and stability under pressure.

Balancing capability, reliability and budget

Cost counts, but not at the expense of performance or service life. Over-specifying for a distant future can waste budget; under-specifying can hit limits within months. A practical strategy is to choose modular systems that can scale, prioritise serviceability and parts availability to cut downtime, and select equipment with proven thermal and mechanical stability for high-cycle automotive and aerospace use. Where shakers are pushed hard in endurance or combined-environment testing, long-term stability is worth more than headline figures.

Testing new materials and structures

Composites, 3D-printed metals and hybrid assemblies don’t always behave predictably, particularly at high frequencies or large displacements. Demand is rising for high-g vibration to expose resonances and structural weaknesses, long-stroke systems for drop, transport and fatigue simulation, and equipment that supports modal and structural analysis as well as screening. As designs get lighter and more intricate, test setups—and the data they produce—must be correspondingly precise.

Integration and system compatibility

Shakers rarely work alone. They must integrate cleanly with slip tables for horizontal testing, head expanders and bespoke fixtures, power amplifiers correctly sized to force and frequency, and digital controllers capable of complex profiles with robust data logging. Poor compatibility wastes time and undermines results, which is why many labs now favour complete, engineered system packages that are designed, proven and supported as one solution.

Why local support still matters

Even the best hardware relies on responsive expertise. A supplier with strong technical knowledge, fast on-site support and a clear grasp of UK and European requirements can make the difference between smooth testing and costly delays.

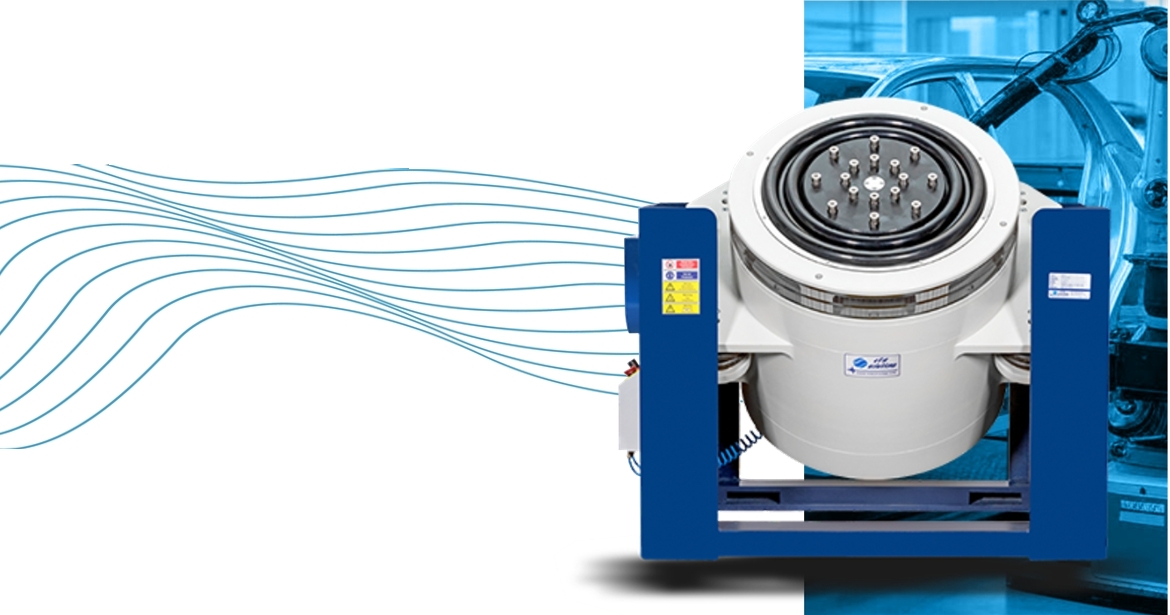

CentraTEQ works with test engineers across the UK to specify, supply and support ETS Solutions electrodynamic vibration shakers—delivering systems that meet modern demands without unnecessary complexity or compromise.

Contact us to discuss your vibration testing requirements.

Visit the CentraTEQ Ltd website for more information on Modern Vibration Testing: Key Challenges Facing Engineers Today