Vibration Testing for Aerospace and Satellite Applications: Matching the Reality of Launch

In aerospace, vibration testing isn’t just about durability—it’s about survivability.

Every component that goes into the air—whether on a satellite, aircraft or launch vehicle—must withstand dynamic forces more extreme and more variable than almost any other sector. Launch profiles, in-flight vibration, shock events and structural resonances all need to be simulated, measured and understood long before the mission begins.

Unlike many industries where vibration testing approximates operating conditions, aerospace demands near-exact replication of real scenarios. It’s not enough to prove a component can survive; engineers must understand how it behaves at each flight stage, with data that is accurate and repeatable to tight tolerances. For satellite payloads and launch hardware, even minor distortion can upset alignment or compromise mission integrity. Test environments must deliver high acceleration, long stroke and clean frequency control to simulate everything from random launch vibration to finely tuned sine sweeps across structural modes.

Compliance with standards such as RTCA DO-160, MIL-STD-1540 and NASA GEVS is essential, but it is only the starting point. Programmes often include additional margin testing, environmental conditioning and profile shaping driven by launch partner requirements. In practice, many profiles are bespoke—built around specific vehicle data or mission parameters—raising the bar for shaker performance. Equipment must not only hit targets but sustain them with minimal harmonic distortion under demanding thermal and mechanical loads.

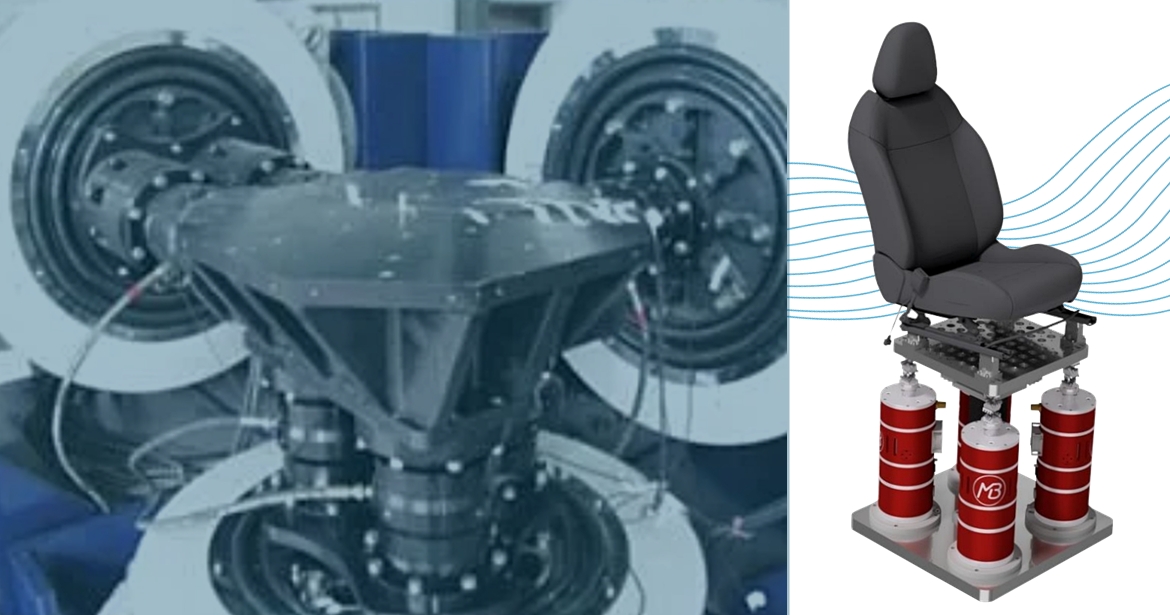

Aerospace programmes frequently require specialised shaker configurations. Compact electronics may call for high-g, table-top systems with precise frequency control, while airframe or system-level work demands long-stroke, high-force shakers for complex assemblies. Multi-axis testing is increasingly important in structural qualification, requiring true simultaneous excitation on multiple axes. This places heavy demands on hardware and control, and on integration: amplifiers must match the performance envelope, slip tables must provide stable motion under load, and fixtures must be engineered to avoid artefacts or unwanted resonances. Even small issues—such as inadequate thermal control or sub-optimal fixture design—can compromise data and trigger costly rework.

Traceability matters. Aerospace test data is scrutinised at every level, feeds qualification records and regulatory submissions, and informs decisions about hardware that may never be recovered. Documentation, calibration and clean data management are therefore as critical as shaker performance. When challenges arise, experienced technical support—people who understand both the equipment and the aerospace environment—keeps programmes on schedule.

CentraTEQ supplies ETS Solutions electrodynamic vibration shakers to aerospace and satellite programmes across the UK. Our systems are used for qualification, screening and endurance testing of commercial aircraft components, launch structures and orbital payloads. Whether for structural-level sine sweeps, high-g component screening or complex random profiles, ETS shaker systems deliver the stability, accuracy and repeatability aerospace engineers demand—backed by the technical support that keeps campaigns running smoothly.

Visit the CentraTEQ Ltd website for more information on Vibration Testing for Aerospace and Satellite Applications: Matching the Reality of Launch