Custom metalwork fabrication

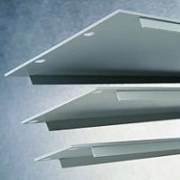

Specialising in fine limit aluminium and light steel fabrication, our range of custom work extends from prototyping one off specials to full production runs, covering anything from small brackets to large multi part assemblies.We continue to invest in new technologies and machinery to constantly improve our fabrication process, so we are able to provide our customers with the cost benefits associated with faster production techniques. However, machines and technology still need skilled operatives, and for some jobs nothing can better the experienced eye of a craftsman. That is why we are proud to have an experienced and talented team of metal work craftsmen, who combine the traditional skills of metalworking with the new process innovations to ensure that our customers receive the highest quality products.

If you are interested to learn what machinery and facilities we have available a summary is provided below.

* The bulk of our punching work is carried out using two twenty two station, CNC, Nisshinbo HTP1000 punches

* For the larger folding work we have multi axes CNC controlled Safan 2.5m multi axis folder and for the smaller work an NC Amada ITS2 folder

* A large proportion of our extrusion punching is carried out on 3 Pierce All Replicating punches

* Cutting is by means of 2m YSD guillotine

* For deburring and brush graining we use a Gridmaster 2000

* The majority of fixings are inserted by 2 Haeger 618s

* Machining work is carried out using an XYZ 1000 mill

* We also have a spot welder and small welding plant together with a range of other powered and manual tools for precision work

Visit the Holt Broadcast Services Ltd website for more information on Custom metalwork fabrication