Assuring EV Battery Pack Reliability at the Cell Interconnect Level

21-07-2023

Electromobility (e-mobility), the move away from using internal combustion engines in cars, bikes, buses and trucks etc., requires batteries to store and release power. The properties of a battery, or rather a battery pack, are therefore largely responsible for setting the vehicle’s performance. Storage capacity defines range and the rate at which power can be released sets acceleration.

In addition, the rate at which the battery pack can accept power determines charge times (in the case of battery EVs [BEVs] and plug-in hybrid EVs [PHEVs], for example) and how much power can be recovered through regenerative braking (in the case HEVs, PHEVs and range extended EVs [REEVs], for example).

A typical battery pack in something the size of a car comprises multiple battery modules, connected using bars, bolts and/or heavy gauge cables, arranged in parallel and series combinations to produce the desired energy and power characteristics. Each module can contain anywhere between a few and more than a thousand cells.

Consider these stats for the battery pack of the Tesla Model S Plaid. It has 99kWh total capacity, of which 95kWh is usable. It has five identical power modules. Each module contains 22 rows (i.e., series connections) of 72 cells placed in parallel (i.e., within each row). This equates to 1,584 cells per module and 7,920 for the pack. Each cell is a Panasonic lithium-ion 18650-type, so larger in diameter and length than a standard AA cell.

Not surprisingly, a vehicle’s battery pack accounts for much of its cost. For a BEV, that can be more than one third. With material costs more or less the same across the industry, all battery pack manufacturers are keen to make their products as cost-effectively as possible. However, they cannot compromise on durability or safety. And regarding this last point, ISO 26262 functional safety standard applies to the battery management systems (BMS) within or working alongside battery packs.

Connections

As mentioned in the Tesla battery example, several cells are placed in parallel. This is typically achieved by connecting the terminals of the cells to busbars. This tends to be done in one of two ways.

Laser welding. Each busbar is placed in physical contact with the respective terminals of all cells to which it is to be connected. Tooling can be an issue to account for any cell height tolerances. Also, as it is a traditional weld process, the objective is to heat metals until they fuse together. Here, there’s a risk that localised heat from the welding process penetrating the negative terminal can alter the cell chemistry and lead to catastrophic thermal runaway. NB: cell positive terminals are ‘floating’, so less vulnerable because of the air gap.

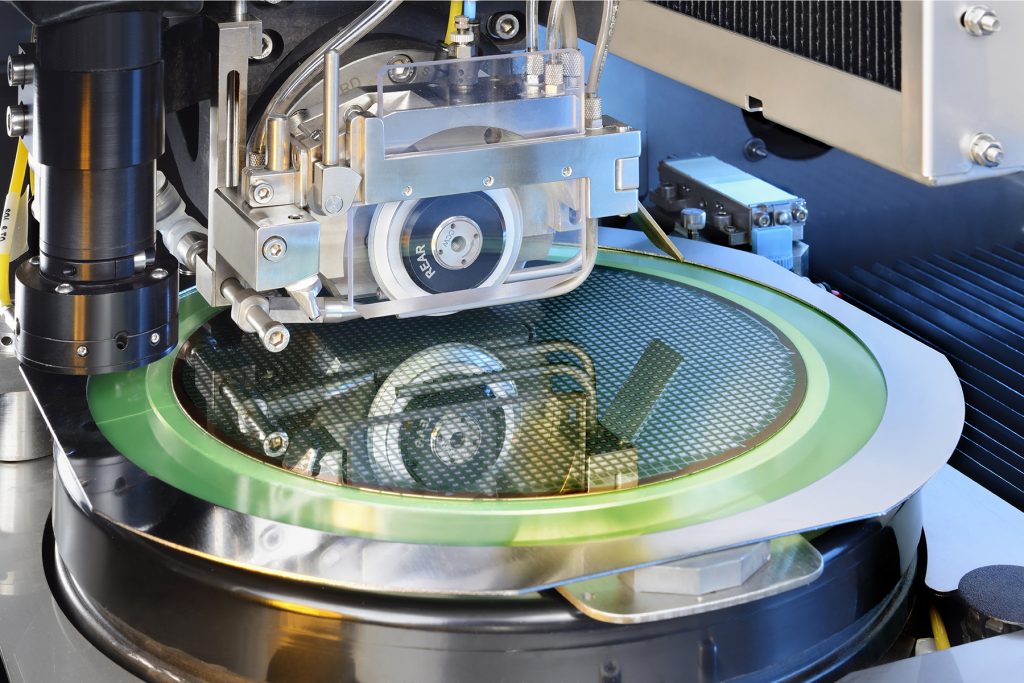

Ultrasonic wirebonding (see figure 1). The process is already dominating power electronics manufacturing as a flexible and robust method of making electrical interconnects in hybrids, switches and regulators; and it dominates the microelectronics industry. Also known as ‘friction welding’, there is minimal localised heating to the wire or battery surface and the process copes far better with tolerances in cell height (relative to the busbar). In addition, there are several industry specifications relating to wirebonding and bond quality that are being adopted within the automotive sector. For example, MIL-STD-883E, Notice 4, Method 2011.7 is a test to measure bond strengths. See figure 2.

As mentioned, durability and safety are key and, in this respect, ultrasonic wirebonding has an edge over welding. Depending on the vehicle’s intended environment of operation, the battery pack may be subjected to significant vibration and mechanical shock. Any interconnect technology used at the cell level must withstand the external forces expected, to ensure a good operational lifetime.

The bond wire tends to be high purity aluminium, with a diameter of between 0.2 and 0.5mm and has a degree of softness and flexibility (annealing). Note: multiple bonds can be made side by side to accommodate high currents.

As for safety, with a suitable diameter, a bond wire can act as a fuse and a failing/shorting cell will effectively self-isolate, thus reducing the risk of fire or explosion.

In Practice

As mentioned, keeping manufacturing costs down is an imperative. But it’s not just the likes of Tesla keeping a keen eye on production costs. For example, Steatite’s Power Business Unit has recently taken delivery of an Asterion EV wire bonder – see figure 3. Steatite specialises in the creation of custom battery packs, which often need to be of a particular size and shape.

The bonder gives Steatite the ability to establish electrical connections using wire bonding in up to half the time spot welding would take, in many cases. In addition, wire bonding makes possible the creation of battery packs with high discharge capabilities and improved performance, as a result of the very low resistance of the bond wire.

Steatite’s engineers have been successfully spot- and arc-welding battery pack components for several years. Spot-welding is, in particular, suitable for the vast majority of the company’s products, in which some parts are up to 3mm thick. Wirebonding is therefore a complement to welding in the manufacture of most battery packs.

On a general note, for any high value manufacturing process, the ability to rework process steps to improve assembly yield is important, especially in the initial prototyping and pilot production stages. In this respect, wirebonding has the edge. Failing or weak bonds can be easily reworked. Moreover, wire bonders like the Asterion EV can automatically perform wire pull tests to verify the bond has taken.

Reworking a failed or imperfect weld is more problematic as there will be more surface material to remove and the cell will be exposed to another temperature process as it is rewelded. Also, depending on its design and once in place, a busbar might not allow access to individual joints for rework purposes.

In summary, welding and wirebonding both have key roles to play in the construction of EV battery packs. As for which process to use, this depends on the pack architecture, ease of access to the parts to be connected, whether or not fuses are required, the ability to accommodate reworks, volumes being manufactured, production costs (including time) and the end application.