Optical Sensor Bonding

DELO KATIOBOND Key FeaturesLight-activated versions can be used in opaque applicationsVery fast curing to minimise process costsEpoxy base ensures dry surface after cureExcellent chemical resistanceOne-part, ideal for manual or automated processing

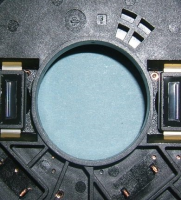

DELO KATIOBOND adhesives are used to bond a PBT-packaged optical sensor onto a thermoplastic housing for an automotive steering application. Positional accuracy of the sensor is critical in x, y, x and theta planes. A heat-cured adhesive is not possible due to the very short cycle times required: < 20 seconds per device. Two sensors per device makes cure time even more critical.

Because both components are dark in colour, so using a pre-activated adhesive is the only solution. Pre-activation is achieved in 2 seconds at 1,000 mW/cm2, and there is enough adhesive visible after the joining process to illuminate for a further 5 seconds at 5,000 mW/cm2 and therefore achieve high initial handling strength. Simultaneous curing of both bond areas using dedicated light-guides meets the cycle time requirement.

Immediately after assembly, the finished components are electrically tested at +85°C, further curing the DELO KATIOBOND adhesive and also increasing the handling strength of the bonded parts. Full testing is then carried out to the most demanding automotive standards.

1234PreviousNext

Light-Activated Adhesives Technical Downloads

File

DELO KATIOBOND Selection Chart

Download

File

DELO PHOTOBOND Selection Chart

Download

File

DELO Bonding in Electronics Brochure

Download

Visit the Inseto (UK) Ltd website for more information on Optical Sensor Bonding