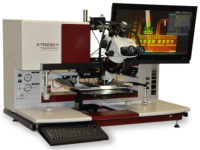

Tresky T-3002-PRO Semiautomatic Die Attach and Die Sorter

Tresky T-3002-PRO Key FeaturesSemiautomatic Die Attach and Die SorterPickup die from up to 200mm wafer Suitable for all kind of Si, GaAs and InP dies down to 30µm thickness Automated Z-Drive with bond force controlTouch-PC control software for ease of setup and operation For: Epoxy, eutectic, solder, flip chip & sinter die bonding processes etc.Precision die to die and die on die placement capabilityIntegrated time pressure dispenser, optional stamping unitSimple to use with excellent ergonomics & high build qualityModular system covers virtually all die pick-place applications

The T-3002-PRO is a high precision, operator controlled semiautomatic die attach and die sorter machine for picking and placing bare semiconductor devices from up to 200mm (8?) wafer or 2/4? waffle packs or GEL paks, passive components and other devices used in microelectronic and related assemblies.

The PRO equipped systems incorporate a motorised Z axis, providing active force measurement on every pickup and placement removing operator induced variation, which is ideal for the bonding of delicate devices and for providing precise control of bondline thickness.

The equipment features superior ergonomic design, high-accuracy and a large 220 x 220mm assembly area with 95mm of Z travel, making it ideal for R&D through low volume production or custom assembly requirements.

Applications include:

Assembly of Hybrid Microelectronic DevicesConductive & Non Conductive Epoxy Die AttachEutectic Soldering of DevicesFlip Chip BondingThermo-compression & Ultrasonic BondingEpoxy Die Attach with Adhesive Dispense or StampingLaser Bar Stacking and UnstackingPCB Chip-on-Board Assembly etc.Die Sorting to Waffle or Gel Pak

All models feature Treskys' True Vertical Technology™, which guarantees parallelism between chip and substrate at any bond height, plus integrated time/pressure dispensers.

The modular T-3002-PRO Die Attach and Die Sort system also includes an extensive range of options, comprising: Beam splitters for Flip-chip applications, Eutectic Scrub & Gas Heating for Eutectic Die Attach, Solder / Epoxy Dispenser, Epoxy Stamping, Pickup Tool Heating, Ultrasonic Bond Heads, Secondary Preform Spindle, Flip Chip Station, Waffle & Gel Pak Tooling, Substrate Holders, Static and Dynamic Heating Plates and alignment / inspection options.

PreviousNext

Tresky T-3002-PRO Die Attach and Die Sort Downloads

File

T-3002-PRO Motorised Z Axis with Pick up from Wafer, Waffle / Gel-Pak etc.

Download

Visit the Inseto (UK) Ltd website for more information on Tresky T-3002-PRO Semiautomatic Die Attach and Die Sorter