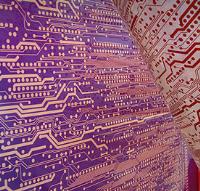

Solder Leveller

The Panels are passed through the flux machine, which cleans the exposed copper leave a layer of flux on the panels.This enables the tin lead to adhere to the copper. The panel is then placed on the arms of the Solder Leveller machine.This machine has a tank of melted tin-lead, into which the panel is inserted vertically for a set amount of time. This ensures that the tin-lead covers all the exposed copper. The panel is then withdrawn at a set speed, and compressed air is passed over it to remove excess tin-lead giving a finish of 10-15 microns.Finally, the panel is passed through a washer system to remove any excess flux.Visit the One Way Holdings Ltd website for more information on Solder Leveller