Case Study: Durable Labelling Solution For Heated Oily Pump

PUMP MOTOR LABELLING SOLUTION - AIR PUMPING / FEBRUUS

Air Pumping approached us earlier this year after searching for a suitable labelling solution. The requirement was for a large label that could be applied to the oily surface of a hot-running pump motor, replacing the previously imprinted metallic plate. The plate could reach temperatures of 60-70°C with the potential to overheat further. Our client initially had concerns about the shape of the label, which would need to adhere to the circular area of the plate while accommodating various bolt holes around the pump motor.

The Labelling Solution:

After assessing the application requirements, we advised our RML-2196 high-performance, durable, abrasion/chemical resistant label construction.

This would meet the spec while offering a robust, durable, oil and abrasion-resistant surface, coupled with an aggressive extra perm acrylic adhesive, providing excellent permanency and durability. This particular label construction is capable of enduring temperatures up to 120°C, which is close to twice the requirement. This provides ample headroom should the application overheat.

Supplied as one piece, the label simply peels away from the roll and features perforated holes to be cut out and applied perfectly over the plate and subsequent bolt holes.

The material for this label is the RML-2916 durable matt silver polyester. The print-guard substrate is a durable scratch-resistant, clear gloss polyester and the adhesive is a permanent, high-tack solvent acrylic for a lifetime bond.

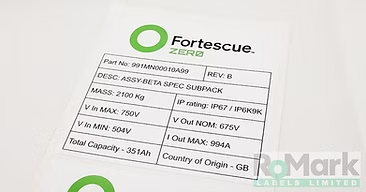

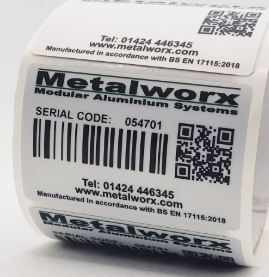

Rating Plate Label

As a side note, Air Pumping had already been using one of our durable, printable labels for the pump motor's rating plate, a cost-effective and increasingly more popular method for providing rating plate information. This label is an industrial-grade metalised polyester, using an ultrabond acrylic adhesive for challenging environments. It is laminated but computer printable, allowing the client to print information, such as the serial number and model as seen above.

We were very pleased with the outcome of this label and so were our clients. There can be a lot to consider when choosing the right label for the job, which is why we always advise speaking with a labelling expert to get the right label for your application bespoke to your requirements. We hope this guide has helped. If you have any questions or you are ready to take your labelling to the next level, give us a call, freephone 0800 023 9277 or drop us an email. We love helping businesses reach their labelling goals.

Visit the RoMark Labels Limited website for more information on Case Study: Durable Labelling Solution For Heated Oily Pump