SYNTHETIC LABELS VS METAL PLATES

27/10/2023

This quick application process translates to increased efficiency, allowing businesses to focus on their core activities.

Adapting To Change

One of the major downsides of metal plates is the time-consuming nature of their preparation. Attaching metal plates often involves riveting, welding, or using adhesives, which can be a labor-intensive and complex process. In contrast, synthetic labels come with a permanent adhesive backing that can be applied effortlessly. This not only saves time but also reduces the need for specialized labor and equipment. With synthetic labels, adapting to changes in labeling requirements becomes a breeze, as labels can be quickly printed and applied as needed.

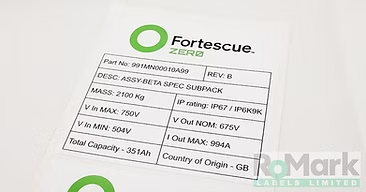

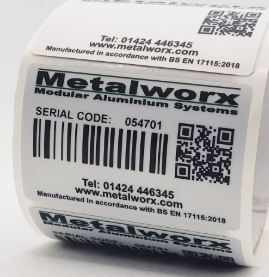

Barcode Utility

The modern business landscape relies heavily on accurate data collection and tracking. Barcodes, QR codes, and serial numbers are essential for efficient inventory management, asset tracking, and supply chain optimization. However, metal plates fall short in this aspect. The process of etching intricate barcodes onto metal surfaces can result in errors and decreased scanning efficiency. In contrast, synthetic labels are designed for compatibility with various printing technologies, ensuring crisp and clear barcode reproduction. This enables seamless integration into automated systems, enhancing overall operational efficiency.

The Cost Factor

While metal plates may have been the traditional choice, they come with a hefty price tag. The time and resources required for etching, preparation, and installation contribute to higher costs. Synthetic labels, on the other hand, offer a cost-effective solution. The streamlined production process and ease of application translate to reduced labor costs and minimal material wastage. Additionally, the versatility of synthetic labels means they can be customized in various sizes and shapes, minimizing waste further.

Bespoke Label Design

One of the standout advantages of synthetic labels is their unmatched versatility. They can be produced in an array of colors, sizes, and shapes to suit specific branding requirements or industry standards. Logos, branding elements, and even intricate designs can be incorporated into the labels, adding a touch of personalization to products and assets. This level of customization is practically unattainable with metal plates, which are limited by their rigid nature.

To Conclude

In conclusion, the era of relying solely on metal plates for durable labeling is giving way to a new era of efficiency, adaptability, and cost-effectiveness with synthetic permanent adhesive-based labels. These labels eliminate the time-consuming processes of etching and preparation associated with metal plates, while also allowing for precise barcode printing and reducing overall costs.

The ability to quickly adapt to changes, the ease of customization, and the seamless integration into automated systems make synthetic labels the clear choice for modern businesses aiming to streamline their operations and enhance their overall productivity.

We want to help you realize the potential of durable labeling for any application. Give us a call, freephone 0800 023 9277 or drop us an email.

Visit the RoMark Labels Limited website for more information on SYNTHETIC LABELS VS METAL PLATES