Equipment Mounting-Fastenings

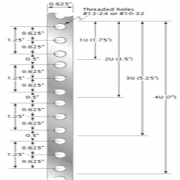

Originally, the mounting holes were tapped to receive a particular type of threaded bolt. This is still frequently used in government and military applications, often in conjunction with slide rails for ease of maintenance. However, it is no longer typical for frequently changed server racks, due to the possibility for the threads to become damaged or for a bolt to bind and break off, rendering the mounting hole unusable. Tapped-hole racks are still used for hardware that rarely changes, such as phone or network cabling panels and relay racks.The tapped-hole rack was first replaced by round-hole racks. The holes are large enough to permit a bolt to be freely inserted through without binding, and bolts are fastened in place using cage nuts. A cage nut consists of a spring steel cage, designed to clip onto the open mounting hole, within which is a captive nut. In the event of a nut being stripped out or a bolt breaking, the nut can be simply removed and replaced with a new one.

The next innovation in rack design has been the square-hole rack. Square-hole racks allow boltless mounting, such that the rack-mount equipment only needs to insert through and hook down into the lip of the square hole. Installation and removal of hardware in a square hole rack is very easy and boltless, where the weight of the equipment and small retention clips are all that is necessary to hold the equipment in place. Older equipment meant for round-hole or tapped-hole racks can still be used, with the use of cage nuts made for square-hole racks.

Visit the SRS Products plc website for more information on Equipment Mounting-Fastenings