Stepper Motor Sensorless Control; What You Need to Know

30-06-2015

So you’re in need of a motor for precise positioning. What would be your preference?

Stepper motor or servomotor?

Many smart engineers like yourself will agree, that the answer lies resolutely in the application requirements.

For example, the compact stepper motor with its ability to run open-loop may be all that’s required for simple tasks, and certainly it makes a very affordable option.

However with high performance dynamic operations, the issues a stepper motor holds around resonance, excessive heat and step-loss often see it take a back seat to the pricier servomotors that utilise advanced control methods.

But things are starting to change.

The introduction of stepper motor sensorless control is already raising eyebrows in the OEM industry.

As it turns out, Nanotec® have found a way to replace expensive stepper motor encoders for virtual encoders within the controller. This means that our faithful friend the stepper motor, can now be operated just like a servomotor but without the high price tag.

Suddenly the query of stepper vs. servo gets interesting; but what does sensorless technology mean for us?

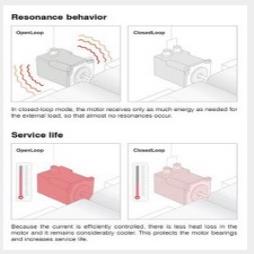

Less heat, no resonance, longer service

With stepper motors receiving a constant stream of full current, it’s no surprise that the resulting increase in high temperatures and vibrations decrease service life and eventually, effectiveness.

However now that the stepper motor can be controlled via the virtual encoder, they are able to receive the required current to perform actions, just like a servomotor. This ensures the stepper motor remains considerably cooler with almost no resonances.

This improved performance protects the motor and its bearings, increasing service life and naturally supplying the added benefit of energy efficiency. Better for the environment and for your bank balance.

Step-loss? What step-loss?

Another argument to avoid stepper motors is the issue of step-loss; missed actions caused by resonances and instability which of course go undetected with open-loop systems.

Nanotec® rectifies this with the closed-loop system that delivers a controlled current to the motor, so that resonances are removed and missed steps (up to its maximum torque) are a thing of the past.

The benefits of the closed-loop system now mean that the controller can recognise inconsistencies in the motor, adjustments can be made and alerts sounded.

And the mechanical issues?

Usually these can be minimised using precise mathematical models and calculating parameters, which let’s be honest, isn’t a quick and simple solution.

Thankfully the Nanotec® sensorless system operates with few parameters and even these can be set using an auto-setup routine that automatically determines all the required parameters. Now we’re talking.

All this additional motor control not only avoids instabilities and step-loss, but Nanotec® noticed that at high speeds, the sensorless control actually worked better than an encoder, even removing speed fluctuations of the motor at low resolutions.

As you can see, the argument for use of sensorless technology grows ever more compelling; yet it seems that’s not all.

Sensorless technology can benefit almost all stepper motor applications with its ability to be combined with open-loop control. When necessary and at low speeds, the system is able to switch to open-loop mode; which still continues to work effectively considering resonance isn’t an issue where only a few steps are needed.

So it seems whether your application deals with speed, or positioning, this combined approach could work for you.

In the end, regardless of your motor preference, there is no denying that the main objective is for your system to run as smoothly and efficiently as possible. We believe Nanotec® have worked hard to provide this for their customers, with a responsive stepper motor that not only uses impressive sensorless technology, but doesn’t break the bank either.

Perhaps this calls for a change of opinion for future precise positioning motors? What are your thoughts?

For more details on a wide range of motors visit our products page or contact us for helpful advice.